The jewelry business has always required a high level of perfection. This has forced it to evolve in different positive ways, particularly in the engraving arena. When a client wants something unique or special engraved on an expensive piece of jewelry, may it be a bracelet, a necklace, or a wedding ring, they expect top notch work. Today, laser engraving technologies have advanced the marking process tenfold, meaning that jewelry designers are now able to attain the highest standard levels though the use of different types of laser engraving machines. These has seen them improving their bottom lines and keeping the costs within manageable levels.

How do laser engraving machines work?

It is important to first understand that laser engraving is a completely different technology from the older methods of item marking. This technique does not involve the use of inks or the use of tool bits that contact the surface that is being engraved. Laser engraving or marking systems are a more modern invention.

But unlike the mechanical machines of the past that used rotary cutters or bits to cut through or mark a surface, a laser beam is used to mark or engrave the surface. A good computer system in this case is necessary as it is used to operate the laser that does the engraving. A suitable software application in this case is vital so as to reproduce highly accurate results. Laser engraving systems are ideal for reproducing serial numbers, graphics, texts and logos in different sized surfaces.

Laser engraving system can reproduce virtually any kind of digital image or text in great detail, even on very small surfaces such as the inside of wedding rings or bracelets. Compared to the traditional forms of jewelry engraving, laser etching or marking is definitely the top performer.

Laser engraving machine sizes

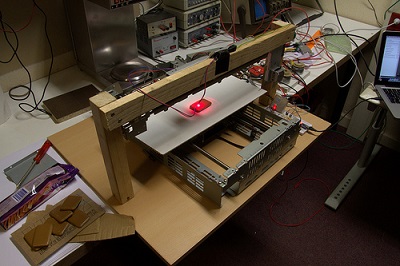

The size of laser engraving machines is small enough to fit almost on any surface being worked on. Gone are the days of using very large pieces of equipment where engraving is concerned. This means a designer has more options in terms of where to conduct his business. The most important engraving devices come in small units that occupy the least space possible. Desktop laser engraving machines today can fit just about anywhere.

Why opt for laser engraving machines?

Apart from their money saving aspect, laser engraving technology also serve a number of other direct purposes. The precision involved when using lasers to mark a surface or embed an image on it when compared to the older and outdated engraving technologies is simply astounding. As a result, laser machines can easily engrave an earring, the back of a watch, outside or inside of a ring, and so forth. Best of all, all tasks can conveniently be done at small stands such those found in shopping malls or in tiny kiosks. As a result, it has become feasible to engrave practically on anything or anywhere on a piece of jewelry. With this, different sized kinds of markings can be made to suit the desires of a customer.

Thanks to laser engraving machines, high precision markings are possible on almost any kinds of jewelry pieces today. So whether made of materials such as sterling silver, gold, tungsten, platinum, palladium, stainless steel, titanium, and many others, laser engraving technique is ideal for etching images, texts, etc. The best reasons for using laser engraving techniques to personalize jewelry pieces is that it offers permanence , affordability, flexibility, precision, quality and much more when compared to traditional forms of marking.

The future of laser engraving machines

With all the potential that laser engraving technology still has in store, there is no telling where the jewelry engraving process will be in the next few years. But you can rest assured that there is no better way to engrave images or texts on a piece of jewelry than laser engraving. With laser engraving machines, jewelry designers today are able to offer better quality of work as well as fulfill customer orders much faster.

A laser cutting or marking machine can be used to reproduce virtually any type of a shape, pattern, texture, text, or image – whatever the client or designer can imagine. Here are some tricks and tips for effective and accurate laser engraving and marking.

• Start by having the right kind of laser machine usage training.

• Level up so as to make even patterns or texts around the inside or outside of a ring. Mini-level equipments are ideal for this purpose.

• Stop reflection by placing a non-glossy piece of paper on the surface being engraved.

• Test your engraving acumen on brass blanks. Before engraving on an actual ring, it is recommended that you first test the laser machine on brass blanks to make sure it will engrave correctly.

• Verify that the laser machine is correctly focused before marking the inside of an actual ring or any other piece of jewelry.

• Consider future sizing as laser marks are mostly forever. As such, before engraving a logo inside of a ring, it is recommended to think ahead so that a future sizing undertaking won’t destroy it.

Comments are closed.