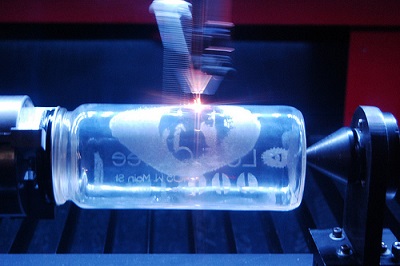

CO2 laser engraving is an intricate process of utilizing charged glass or metal laser tubes to mark the surface of different materials including but not limited to metal, wood, alloys, stone, acrylic, or glass. While the majority of metals are engraved or etched with fibre lasers that have a focused spot size, laser engraving in Sydney is considered one of the best etching techniques available nowadays.

The method is exceptionally precise, and can be used utilized for a wide range of marketable applications while requiring low maintenance. Most importantly, since laser marking technology has greatly evolved over the years, it is one of the most efficient surface marking methods you can ever think of. The majority of people are simply blown away when it comes to laser engraved designs. In most cases, the finished object sells itself allowing sellers to get top prices for work that might have taken around 30 minutes at the most.

Benefits of laser engraving on glass

Laser etching involves producing gorgeous words and pictures on objects, more than usual on glass, by leaving behind a lasting mark. Let’s now discuss a few merits of laser engraving on glass.

• Accuracy

A laser etches with extreme precision, meaning that the final results are way more accurate than using any other engraving equipment, for example CNC routers. A CNC router is limited to corners due to the size of the bit whereas laser spot size is much smaller and can mark fonts as small as 3 points.

• Cost

There are notable cost reductions where lasers are used to mark a surface. Moreover, laser engraver prices have greatly dropped to a point that most are starting to move back up. Quite a number of inexpensive engravers can be found on reputable online stores for your selection. Due to advances in etching technologies, individual product engraving prices has also dropped.

If you want to purchase the best engraving machinery, it is recommended that you do so through a reputable company with good technical support. That being said, you can view examples of laser engraved glass almost anywhere, meaning that laser marking services have become exceedingly common today. This has assured a balance between the supply and demand.

• Speed

Laser etching is an extremely fast process. All that is required of a client is to send an image in almost any file format to an engraving machine or to a laser engraving service provider and within a few hours, you got the markings you want. The end results are amazing 2D or 3D photos perfectly engraved on stone, acrylic, glass, or an assortment of other materials. The actual etching time, however, depends on the complexity of an image. In most cases, an engraving service provider takes around 1-4 business days to work on complex glass engraving projects. Projects that take more than two days are much more expensive compared to those that take only a few hours. While conventional hand engraving techniques are pretty time and effort consuming, laser engraving is comparably fast and reliable.

• Ease and simplicity

The engraving process is quite simple. All that is required of you is to supply a high definition photo, preferably one with a resolution higher than 1260 x 800. This image is then converted into a photo crystal using modern laser etchers. Because laser beams are non-invasive, no marks or blemishes are left on the crystal’s surface. Laser engraving is an exceptionally safe process and that creates durable end results.

All in all, laser engravers enable people to create awesome medals, gifts, awards, to name but a few. A 2D image is first converted into an amazing 3D design to perfectly fit inside the surface being etched. The image is then engraved using a high quality laser for end results like no other. So, we can comfortably say that CO2 laser engraving on glass is certainly worth thinking about.

Comments are closed.